Way back in 2012, Penland School was planning a new house for its core fellows: those energetic and committed artists who live and work at Penland–taking classes and doing work for the school–for two years. They amaze us, we fall in love with them, and they move on to other things. Fortunately, as illustrated in this picture, some of them move on to things that keep them at Penland.

The design for the new house, by architect Louis Cherry, includes a feature called a trombe wall, which is a dark-colored masonry wall that collects and radiates solar heat in the winter. Jean McLaughlin, who was Penland director at that time, along with the design committee for the project proposed that this wall should also be an artist-generated design feature.

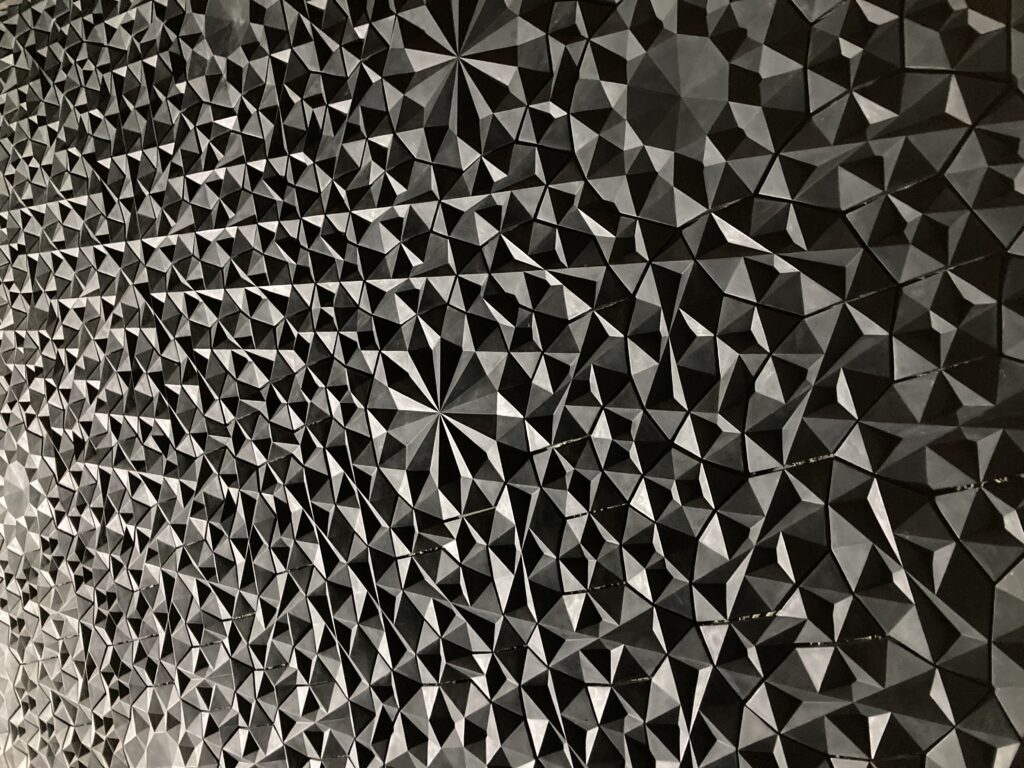

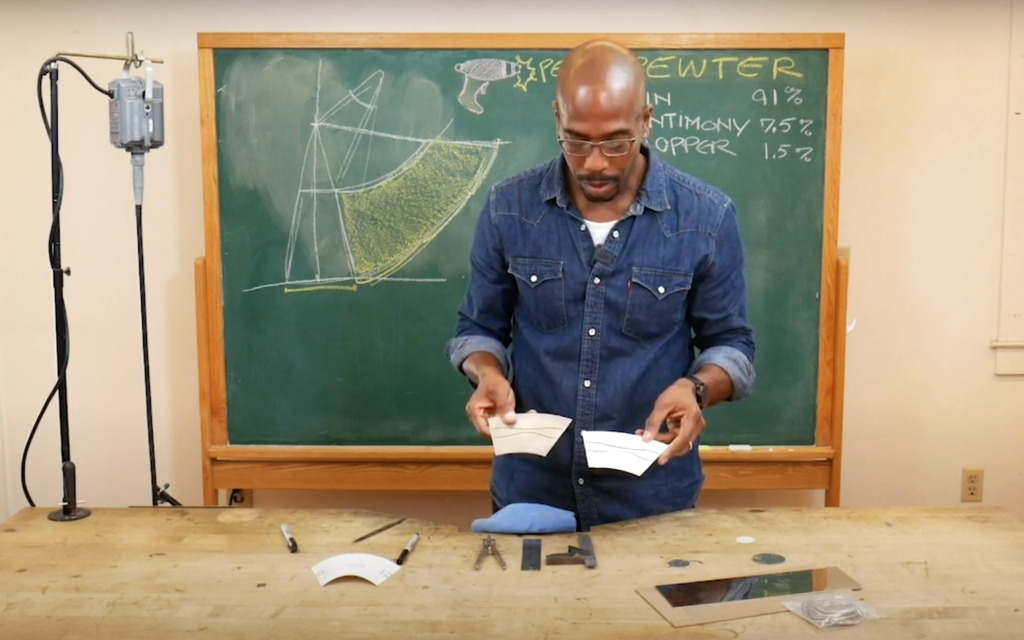

The artist selected was Ian Henderson, who had completed the core fellowship earlier that year. Ian is a bit obsessive about pattern, and he had done quite a bit of slip casting while he was in the core program. Out of those interests grew a proposal for a relief tile installation with an underlying design based on a set of shapes known a girih tiles, which are the basis for a centuries-old system of ornamentation used throughout the Middle East. Ian readily points out that it is a derivative design. “Plenty of people before me have been exploring these same shapes and patterns. If the design for this installation is innovative, it is in the creation of a topography for each tile that is made up of triangular facets.”

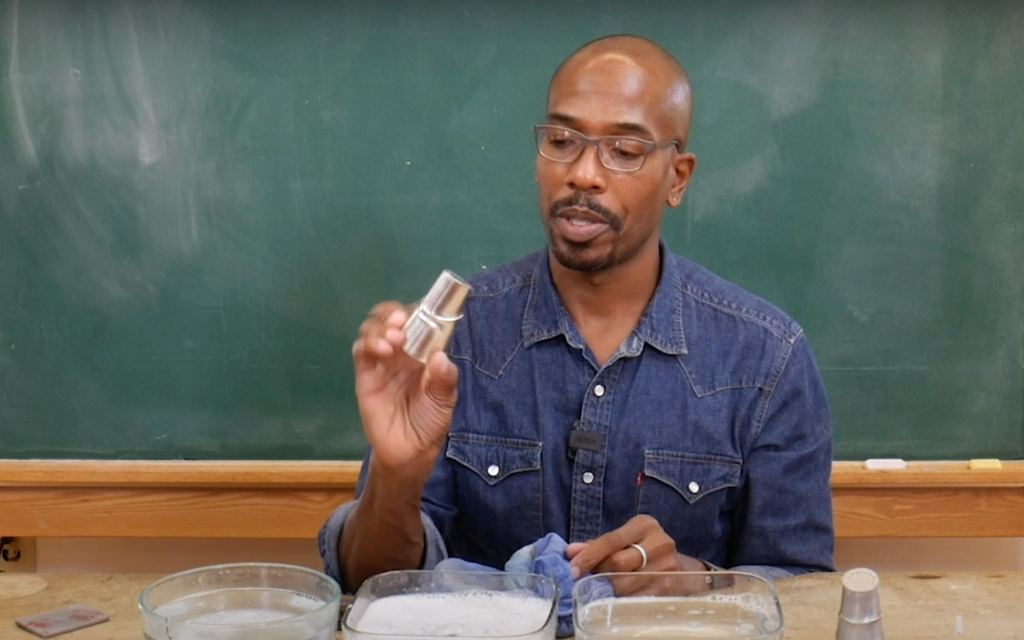

With able assistance from fellow core alumni Daniel T. Beck, Andrew Hayes, and Mark Warren, Ian made about 1,000 ceramic tiles during a 2013 residency at the Kohler factory in Wisconsin. He documented that residency in a fascinating blog that covers both the design process and the making of the tiles. At the end of three months, the tiles were packed up and shipped to Penland where they were put into storage to wait for the house to become a reality.

This took a little while. Construction at Penland always waits for fundraising, and then it takes as long as construction takes. Fast forward to February of this year, and the house had finally reached a stage where the tiles could be installed. Ian Henderson is now Penland’s director of operations, and Daniel Beck has been iron studio coordinator for almost a decade. Their plan had always been to install the tiles together when the time came, and when the time came, they were both working at Penland.

The wall sits just inside the front entrance where future generations of core fellows will walk past it as they retreat to their lovely house for some much-deserved rest or head up to campus to work on some equally ingenious project.

————–

In the time since the Kohler residency, Ian has also created a concrete-tile installation with students in Guanajuato, Mexico and another for the Center for Craft in Asheville, North Carolina.

If you would like to learn more about girih tiles, they are beautifully explained in this lecture by Peter Lu, whose work has greatly increased contemporary understanding of the system.